Discover

RotoMill.

Recover one barrel of oil for every tonne of drilling waste processed and lower your drilling waste management green house gas emissions by more than 50%.

Learn more

50% of your drilling waste is oil you can recover

Our specialists streamline drilling waste processing onsite, returning up to one barrel of oil for every tonne of drill cuttings processed. Eliminating the need for costly logistics, we lower the total cost of your operation and reduce your carbon footprint.

Overview

The safest, most efficient way to handle and process drilling waste.

Our market leading drilling waste processing technology, the RotoMill, is the safest and most efficient way to process drilling waste at the wellsite or at a centralised processing site.

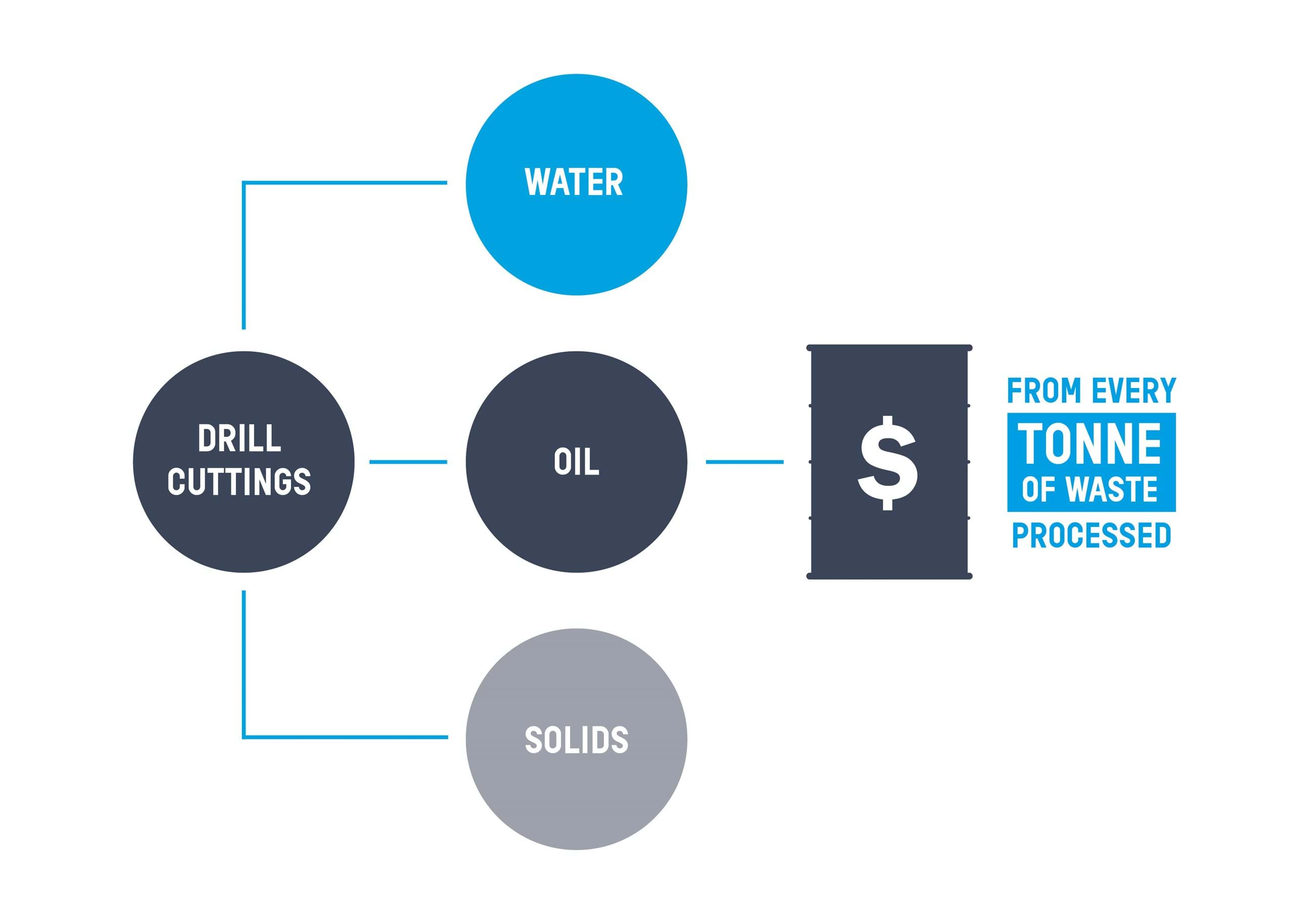

The RotoMill uses a process of thermal desorption to separate drill cuttings and associated materials into their three constituent parts – oil, water and solids – for recycling and reuse.

Process Outputs

Recover 1bbl of oil for every tonne processed.

Recovered base fluid has zero degradation compared to virgin base fluid, due to pre-determined temperature within the mill chamber. It

is then recycled back into the drilling fluid system.

Recovered water can be used to wet down the recovered powder. It can then be discharged following testing and confirmation that it meets any

prescribed discharge requirements <5,000 PPM, typically <1,000PPM.

Recovered solids have hydrocarbon content <0.5% and typically <0.1%.

These solids are classed as inert and suitable for disposal at site.

Environment

Lower your drilling waste management green house gas emissions by 50%.

Our industry-defining technology converts drill cutting waste into resources you can reuse and recycle at the wellsite to promote sustainable operations. Recovered oil is recycled directly back into the active mud system at site, while inert solids and processed water can be safely disposed of at site.

By eliminating all logistics associated with transporting waste offsite for treatment and disposal, TWMA's wellsite processing solutions will lower your drilling waste management green house gas emissions by more than 50%.

Key Benefits

Eliminating Costly Logistics Expenditure Is Just The Beginning

By processing drill cuttings at the wellsite, operators can reduce total cost of ownership by up to 40%. This is achieved by eliminating shipping and logistics and waiting on weather downtime associated with skip and ship operations.

Processing drilling waste on-site significantly reduces the number of lifting operations by up to 95% (compared with skip and ship operations).

Not only does this reduce safety risk to personnel, but also eliminates waiting on weather risk, allowing your drilling operations to continue in adverse weather conditions where lifting operations are often suspended.

By eliminating vessel and trucking requirements associated with a skip and ship operation, green house gas emissions of a typical drilling waste operation are reduced by more than 50%.

FEATURES & BENEFITS

Eliminates the transport of drilling waste onshore

Re-use valuable base fluid in the drilling mud system

Eliminates waiting on weather risk

Significantly reduces your carbon footprint

Eliminates lifting operations

Reduces total cost of ownership

Safest method of waste handling and processing

The smallest system footprint in the market

Technical Details

Designed For Efficiency & Delivering Significant Returns.

Mobile & flexible

The RotoMill can be operated by either diesel engine or electric motor for added operational flexibility. The unit, which is the smallest in the market, can be configured to fit available deck space.

Drill faster

The RotoMill system complete with buffer storage enables you to set record drilling rates of penetration safely and efficiently.

Environmental performance

Proven to lower your drilling waste management green house gas emissions by more than 50%.

Automated system

A fully automated system with ability to process drill cuttings up to 10MT/hr.

XLink™

Automate your operation.

Upgrade your wellsite processing system with XLink™ to optimise drilling performance and deliver greater drilling insights to your operation.

TWMA’s XLink™ is a hardware and software system that can be installed on any TWMA equipment to give real time condition monitoring. View system performance and trend analysis online at any time, anywhere in the world through TWMA’s secure online portal.

The innovative system reduces POB, improves operational insights, and automates your wellsite processing system to lower cost, improve safety and lower carbon emissions.

Real-World Results

Quality engineering.

Proven performance.

-

Case Study

Case StudyRotoMill® recovers base oil worth $24m.

TWMA recovers base oil worth $24m with world first at source drilling waste handling, containment and treatment solution.

Author -

Case Study

Case StudyTWMA reduces well cost by 35% on North Sea campaign.

TWMA delivers $1.2m in savings over a two well campaign representing a 35% cost saving compared to skip and ship.

Author -

Case Study

Case StudyPioneering solution delivers value worth $18.5 million

TWMA pioneers drilling waste management solution to process over 50,000MT in legacy waste streams on one of the UAE’s largest fields.

Author -

Case Study

Case StudyTWMA saves AGR more than $500k with TCC RotoMill®

TWMA reduces total cost of ownership by 35% across a one well campaign.

Author -

Case Study

Case StudyTWMA offshore processing reduces Co2 emissions by 50%.

Environmental study shows TWMA drill cuttings offshore processing solution reduces carbon emissions by 50% compared to skip and ship.

Author

DELIVERING VALUE AT EVERY TURN.

With over two decades of experience in transforming drilling waste operations for our clients, we have built an esteemed reputation of reliability.

Sandy WoodSenior Group Business Development Manager

How Much Can You Save?

Discover how much your drilling waste management solution could save you.

Need Solids Control Solutions?

Explore our solids control solutions for water and oil-based mud systems.

Looking For Products?

Browse our high-quality products and equipment that keep you turning.