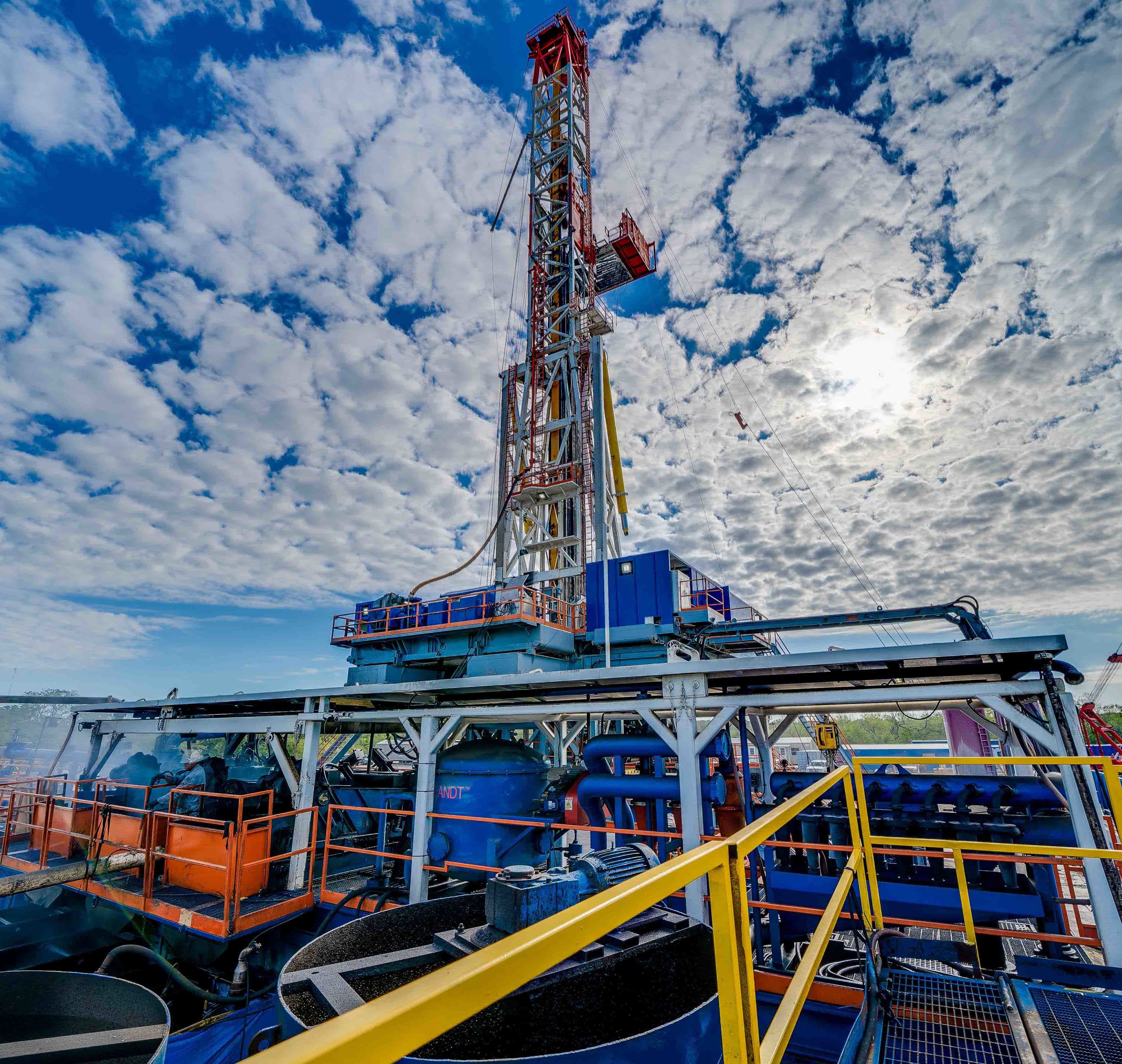

Solids Control

Oil-Based Systems

Market leading solutions to recover base fluid at source.

Explore This Solution

Overview

CUSTOMISED RELIABLE SOLUTIONS TO DRIVE SUSTAINABILITY AND COMBAT NPT.

This solution allows the recovery of oil from spent drilling fluid and drill cuttings and can be reused in the drilling process.

The solution works in two forms. Spent drilling fluid is recovered from the shale shaker, drying shaker underflow or active system. It is then treated at source to recover base fluid and any light solid contamination. In parallel to this drill cuttings can be treated with a vertical cuttings dryer to recover mud and base fluid; this is additionally treated via a decanting centrifuge.

The ultimate goal is to sperate fluid and solid fractions, to minimise and potentially eliminate haul off from site and maximise recovery of base fluid and drilling mud for reuse at source, thus creating a sustainable solution for your operation.

Operating detail

LEADING PROCESS TO REDUCE DRILLING WASTE & MAXIMIZE VALUE.

Processing drilling waste effectively with TWMA technology in turn eliminates pit and environmental hazards.

Our pit-less closed loop system has a high level of capability to drastically improve your space utilization and capacity, without increasing the footprint.

A 30% plus reduction in overall pad footprint delivers significant savings in both construction materials and time, whilst eliminating pit construction and environmental hazards - significantly reducing your environmental liability.

FEATURES & BENEFITS

Reduction in haul off for disposal, in some cases disposal of solids on location, eliminating disposal costs

Ideal for Dry/Zero Discharge Locations and areas with strict environmental regulations

Skid mounted system allows for easy mobilisation rig up and demobilisation from our clients’ location

High capacity technology capable of handling high ROP’s at source

Technical Details

SPECIALISTS WITH THE TECHNOLOGY YOU CAN TRUST.

Our process guarantees above standard outputs on our fluid recovery and solids controls.

TWMA’s high-performance technology and processes reclaim base fluid from the rig site solids control equipment and return it to the system quickly.

Product Sales

As a trusted supplier of essential on-site equipment, we have a variety of high-quality products designed to keep your operation turning.

As a trusted supplier of essential on-site equipment, we have a variety of high-quality products designed to keep your operation turning.

Real-World Results

Quality engineering.

Proven performance.

-

Case Study

Case StudyPit & tank cleaning solution reduces slops by 60%.

TWMA trained specialists complete pit and tank cleaning to improve safety performance and efficiency.

Author -

Case Study

Case StudyRotoMill® recovers base oil worth $24m.

TWMA recovers base oil worth $24m with world first at source drilling waste handling, containment and treatment solution.

Author -

Case Study

Case StudyTWMA saves AGR more than $500k with TCC RotoMill®

TWMA reduces total cost of ownership by 35% across a one well campaign.

Author -

Case Study

Case StudyTWMA reduces well cost by 35% on North Sea campaign.

TWMA delivers $1.2m in savings over a two well campaign representing a 35% cost saving compared to skip and ship.

Author

ELIMINATE WASTE COSTS & LOGISTICS.

Processing drilling waste effectively with TWMA technology eliminates pit and environmental hazards.

ROBERT CASKEYUS Sales Manager

Seeking Seamless Integration?

Our wellsite solutions return more value when they work together.

Need Wellsite Processing Solutions?

Explore our world leading solution for drilling waste processing.

Looking For Products?

Browse our high-quality products and equipment that keep you turning.